| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : JN

Model Number : JN-SFA-10

Place of Origin : CHINA

Certification : ISO9001

MOQ : 100PCS

Price : Negotiable

Packaging Details : By Sea Pallet /By Air Carton / By Express Packaging

Delivery Time : 25 Days

Payment Terms : L/C,T/T

Supply Ability : 200K PCS/Month

Coating : SS316(or 304) Stainless Steel Tube

Application : Food Processing Industry, Mining Industry Automotive, Electronics, Medical, Etc.

Process : Sintered

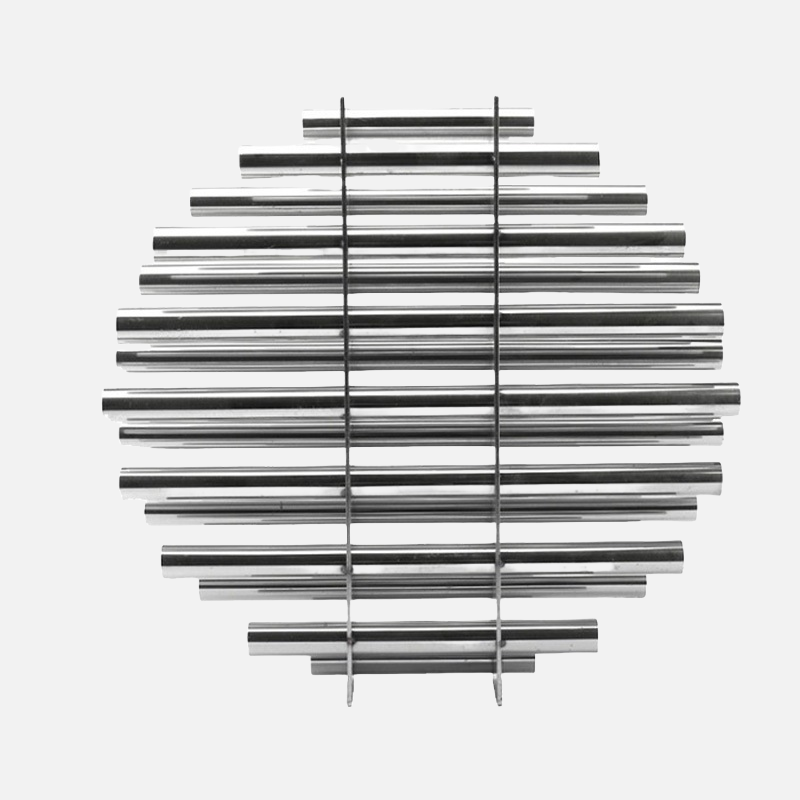

Shape : Grid Or To Order.

Magnet Material : Neodymium Iron Boron (NdFeB) Or AlNiCo /SmCo

Size : Made To Order

Our Permanent Magnet Assembly is a high-quality, customizable product designed for a wide range of industrial applications. Made with top-of-the-line materials and advanced manufacturing processes, our Permanent Magnet Assembly is built to last and deliver exceptional performance.

The Permanent Magnet Assembly is a magnetic core assembly that is used in a variety of industries, such as food processing, mining, automotive, electronics, medical, and more. It is made to order, ensuring that it meets the specific needs and requirements of each individual customer. The magnet material used can be either Neodymium Iron Boron (NdFeB) or AlNiCo/SmCo, depending on the specific application and environment.

The assembly takes the form of a grid or can be customized to any shape required by the customer. This allows for a more precise fit and better performance in the intended application.

Order your Permanent Magnet Assembly today and experience the exceptional performance and durability of our top-quality product. Contact us for more information or to request a quote.

| Property | Value |

|---|---|

| Process | Sintered |

| Application | Food Processing Industry, Mining Industry Automotive, Electronics, Medical, Etc. |

| Coating | SS316 (or 304) Stainless Steel Tube |

| Magnet Material | Neodymium Iron Boron (NdFeB) or AlNiCo/SmCo |

| Shape | Grid or Customized |

| Size | Customized |

| Magnetizing Component Assembly | Included |

| Powerful Magnet Assembly | Yes |

| Constant Magnetic Field Assembly | Yes |

| Magnetic strength | ||||||||

Magnetic rod outer diameter | 4000GS | 5000GS | 6000GS | 7000GS | 8000GS | 10000GS | 11000GS | 12000GS |

| Φ6(0.24") | √UH | - | - | - | - | - | - | - |

| Φ8(0.31") | √UH | - | - | - | - | - | - | - |

| Φ9(0.35") | √UH | - | - | - | - | - | - | - |

| Φ10(0.39") | √UH | - | - | - | - | - | - | - |

| Φ12(0.47") | √UH | √UH | - | - | - | - | - | - |

| Φ16(0.63") | √UH | √UH | √UH | - | - | - | - | - |

| Φ19 (0.75") | √UH | √UH | √UH | √UH | - | - | - | - |

| Φ20.3(0.80") | √UH | √UH | √UH | √UH | - | - | - | - |

| Φ22 (0.85") | √UH | √UH | √UH | √UH | √UH | - | - | - |

| Φ25 (1.00") | √UH | √UH | √UH | √UH | √UH | √UH | √N | √N |

| Φ32 (1.25") | √UH | √UH | √UH | √UH | √UH | √UH | √N | √N |

| Φ38 (1.50") | √UH | √UH | √UH | √UH | √UH | √UH | √N | √N |

| Φ50 (1.75") | √UH | √UH | √UH | √UH | √UH | √UH | √N | √N |

| Φ63(2.48") | √UH | √UH | √UH | √UH | √UH | √UH | √N | √N |

Brand Name: JN

Model Number: JN-SFA-6

Place of Origin: CHINA

Certification: ISO9001

Minimum Order Quantity: 100PCS

Price: Negotiable

Packaging Details: By Sea Pallet /By Air Carton / By Express Packaging

Delivery Time: 25 Days

Payment Terms: L/C,T/T

Supply Ability: 200K PCS/Month

Process: Sintered

Application: Food Processing Industry, Mining Industry Automotive, Electronics, Medical, Etc.

Size: Made To Order

Shape: Grid Or To Order.

Coating: SS316(or 304) Stainless Steel Tube

The Permanent Magnet Assembly by JN is a high-quality and reliable magnetizing component assembly made using a sintered process. It is designed to be used in various industries such as food processing, mining, automotive, electronics, medical, and more.

The assembly is made to order, ensuring that it meets the specific requirements of each client. It is available in different sizes and shapes, including a grid shape or a custom shape according to the needs of the application.

The permanent magnet assembly is coated with SS316 (or 304) stainless steel tube, making it durable and resistant to corrosion. This ensures a longer lifespan and better performance in various environments.

The JN Permanent Magnet Assembly is suitable for a wide range of applications and is commonly used in the following industries and scenarios:

The JN Permanent Magnet Assembly is available for order with a minimum quantity of 100 pieces. The price is negotiable, and the delivery time is approximately 25 days, depending on the order quantity and destination.

The assembly can be shipped by sea pallet, air carton, or express packaging, according to the client's preference. Payment can be made through L/C (Letter of Credit) or T/T (Telegraphic Transfer). With a supply ability of 200K pieces per month, JN can fulfill large orders with consistent quality and timely delivery.

Choose JN Permanent Magnet Assembly for your next magnetizing component assembly needs and experience the highest level of quality and performance.

Our Permanent Magnet Assembly is carefully packaged and shipped to ensure safe delivery to our customers.

The magnets are first placed in protective foam or plastic trays to prevent any damage during transit. The trays are then placed in sturdy cardboard boxes with sufficient padding to absorb any impact. The boxes are sealed and labeled with the product name, quantity, and handling instructions.

For international shipments, the boxes are further placed in wooden crates for added protection. The crates are marked with the necessary shipping information, including the product details, destination address, and handling instructions.

We work with reputable shipping companies to deliver our products to our customers. Our team carefully tracks and monitors the shipment to ensure timely and safe delivery.

Upon arrival, customers are advised to carefully inspect the packaging for any signs of damage. In the unlikely event of any damage, please contact us immediately for assistance.

We strive to provide the best packaging and shipping services to ensure that our Permanent Magnet Assembly reaches our customers in perfect condition.

|

|

Magnetic Core Assembly Coating SS316 Stainless Steel Tube Made To Order Images |